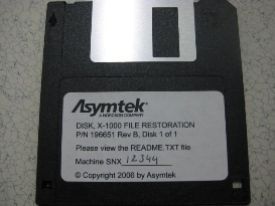

Asymtek 1020 Dispenser

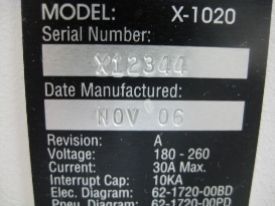

Model Number: X-1020

Serial Number: X12344

Year Nov 2006

DJ9000 Pump Head

The X-1020 system offers precise control over positioning accuracy using sealed glass linear encoders.

Features

Provides enhanced fluid dispensing control with choice of jet or pump: DJ-9000 DispenseJet, DP-3000 linear positive displacement pumps and DV-7000 Heli-flow™ pumps

Supports a full range of applications, including flip chip and CSP underfill, dam and fill, die attach, and thermal compounds

Unique CAN bus architecture for efficient operations now, and simplified integration for future improvements

Closed-loop linear-encoded X-Y positioning system with fast-motion acceleration ensures high throughput

All new and enhanced pattern recognition system with red/blue LEDs for a larger dynamic range of lighting

No periodic calibration required

No special needles required

Backwards-compatible software – customers can use existing dispensing programs

Many Asymtek pumps already work with the X-1020 – protecting investments in pumps and valves

Recommended Applications

Underfill for flip chip and chip scale packaging

Chip Encapsulation

Dam and Fill

Solder Paste

Thermal Compounds

Productivity Enhancements

- Dual Lane Configuration

- Dual-Action Dispensing

- Dual-Simultaneous Dispensing

- Low Fluid Sensors

- Custom Heated Tooling (impingement or contact)

- Process Development Hot Plate

- SECS/GEM Interface Software

- Slim Line Height Sensor

DJ-9000 DispenseJet® Valve

Speed, Flexibility, Process Control, Experience

Jetting is the best way to dispense many fluids quickly and accurately. With Asymtek's new DispenseJet DJ-9000, jetting is faster and simpler than ever. Based on the award-winning DJ-2100 series, the DJ-9000 has a high shot-generation rate, can be cleaned in a few minutes, and has fast changeover of wetted parts.

Jetting offers many advantages over traditional needle dispensing to deliver speed, quality, and low cost of ownership.

- Speed: high flow rate up to 400 mg/second; high shot rate up to 200 dots per second; no Z-axis motion; jets "on the fly" - no stopping between dots required; less height sensing required; no needle backtracking to prevent fluid stringing.

- Quality: High wet-dispense accuracy; smaller wet-out areas; round, uniform dots;

improved line quality with no "dog-bones" and improved line knit. - Avoid common problems: No bent needles; no chipped die; no dripping; reduced part interference; no effects from warpage; no corner buildup.

- Low Cost of Ownership: Easy and quick to clean in 10 minutes or less; maintenance is tool-free; less waste of fluid due to small wetted path; consumable parts are lower cost; no under-board support required.

You'll benefit from capabilities beyond traditional needle dispensing:

- Jets in tight spaces as small as 175 micrometers

- Small fillet sizes as small as 300 micrometers

- Dot diameter as small as 200 micrometers

- Shot volumes as small as 1.0 nanoliters

- Jet stream size as small as 50 µm

- Slim design increases dispense area.

- Jets fluids from 1 to 250,000 mPa (cps)

In operation, the jet "flies" over the part or substrate, and using a patented high-speed mechanism, shoots precise volumes of fluid in dots, lines and patterns. Jetting multiple shots in the same location creates larger dots. Lines and complex shapes are constructed from adjacent dots. Dispensing consistency is improved with active temperature controls.

With the Calibrated Process Jetting (CPJ) feature, volumetric repeatability can be maintained during long production runs to improve process capability (Cpk). Dispense patterns are programmed with a specified weight. CPJ periodically samples the dispense weight per shot, then computes the number of shots for each pattern. With this information, CPJ optimizes line speed based on maximum specified shot interval.

Features

- Jets a wide range of fluids including underfill, SMA, encapsulants, conformal coating, UV adhesives and silver epoxy

- Fast - jetting eliminates z-axis motion

- Accurate - jetting is highly repeatable

- Easy to use and maintain

- Small wetted path so less fluid is wasted

- One model handles multiple applications

- Dot diameter as small as 200 micrometers (0.008 in.)

Complete - Good Functional Condition

Price: $65,000

Asymtek 1020 Dispenser

See more photos below

© 2010 First Place Machinery Corporation.